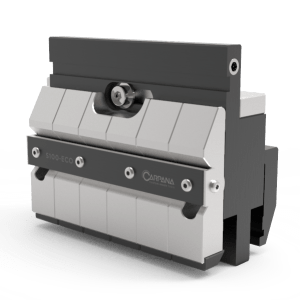

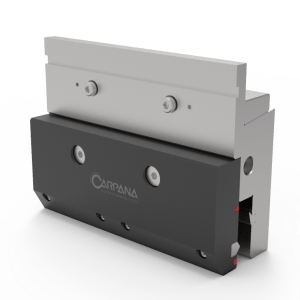

Upper fast clamping system for Promecam tang.

Pneumatic version:

Possibility to manufacture it on request in different height up to 400mm

S.ECO.100, S.ECO.150, S.ECO.200, S.ECO.250, S.ECO.300, S.ECO.350

We produce CLAMPING SYSTEMS FOR PRESS BRAKE:

Features

Strength points

• Reduced dimensions

• Vertical tool change (for front clamp)

• Automatic tool lifting and seating

• Max. flexibility in clamping and removal of segmented tools thanks to front segmented and independent inserts

• Possibility to move intermediates closer

• No extra space required for connection pipes; as they are in the upper clamping area, sheet metal bending area is free

• System suitable to clamp Promecam type tools not exceeding 25kg weight per section

Promecam tang 7mm axis

Pneumatic supply with retractable pipe (two intermediates can be brought completely together. No space required for fittings)

Crowning wedge

Intermediate

Manual rear clamp

Pneumatic front clamp

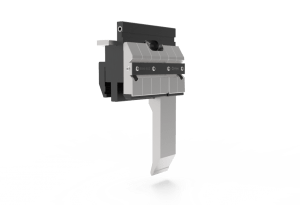

Series of independent and segmented plates. When a tool is inserted or removed, only the involved plates are moved while the others remain in their original position.

For example, a 50 mm long segment moves two plates only, while the others remain in place.

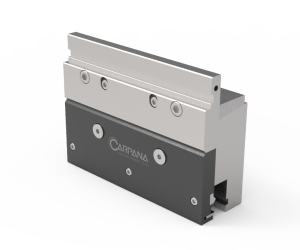

Features

• Material C45

• Max capacity 100 T/m

• Length 150mm

• Double clamping (hydraulic front clamp and manual back clamp)

• Working pressure 30 Bar

Strength points

• Reduced dimensions

• Vertical tool change (for front clamp)

• Automatic tool lifting and seating

• Good flexibility in segmented tools clamping and removal thanks to front inserts cut in two independent parts

• Connection pipes are in the upper clamping area, so sheet metal bending area is free

• System suitable to clamp Promecam type tools not exceeding 35kg Weight per section

Promecam tang

Hydraulic supply

Crowning wedge

Intermediate

Manual back clamp

Front clamp

Hydraulic supply

Promecam tang

Crowning wedge

Intermediate

Manual back clamp

Front clamp

Features

• Material 42CrMo4

• For tools with head thrust

• Max capacity 150 T/m

• Length 200mm

• Working pressure max 16 Bar

Strength points

• Reduced dimensions

• Vertical change of punches equipped with quick release button or horizontal tool change of punches with antifall pins

• Automatic tool lifting and seating

• Possibility to move intermediates closer

• No extra space required for connection pipes; as they are in the upper clamping area, sheet metal bending area is free

Promecam tang 7mm axis

Pneumatic supply with retractable pipe (two intermediates can be brought completely together. No space required for fittings)

Crowning wedge

Intermediate

Pneumatic front clamp

Features

• Material 42CrMo4

• For tools with head thrust

• Max capacity 150 T/m

• Length 200mm

• Working pressure 30 Bar

Strength points

• Reduced dimensions

• Vertical change of punches equipped with quick release button or horizontal tool change of punches with antifall pins

• Automatic tool lifting and seating

• Intermediates can be moved closer to min. 50mm distance

Features

• Material 42CrMo4

• For tools with head thrust

• Max capacity 150 T/m

• Length 200mm

• Working pressure 16 bar pneumatic

Strength points

• Reduced dimensions

• Vertical change of punches equipped with quick release button or horizontal tool change of punches with antifall pins

• Automatic tool lifting and seating

• Possibility to move intermediates closer

New Standard tang

Pneumatic supply. No extra space required for connection pipes; as they are in the upper clamping area, sheet metal bending area is free

Features

• Material 42CrMo4

• For tools with head thrust

• Max capacity 150 T/m

• Length 200mm

• Working pressure 30 Bar

Strength points

• Vertical change of punches equipped with quick release button or horizontal tool change of punches with antifall pins

• Automatic tool lifting and seating

• Intermediates can be moved closer to min. 50mm distance

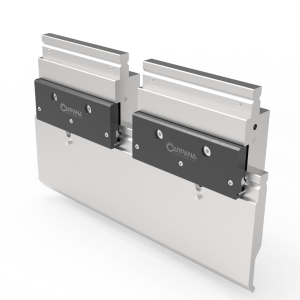

Features

• Material 42CrMo4

• For tools with head thrust

• Max capacity 250 T/m

• Length 223 mm

• Working pressure 15 Bar HYDRAULIC (16 Bar PNEUMATIC)

Strength points

• Reduced dimensions

• Vertical tool change of punches with antifall pins

• Automatic tool lifting and seating

• No extra space required for connection pipes

Special reinforced clamping system mounted directly to the press brake upper beam

Crowning wedge

Intermediate

Hydraulic supply with retractable fitting

Hydraulic front clamp

Insert for punch lifting and seating

Polyurethane insert to clamp segmented tools properly

Upper fast clamping system with Promecam tang with 7mm bending axis. For tooling with RFA tang

AXS.PLUS/RFA.144

Features

• Material 42CrMo4

• For tools with head thrust

• Max capacity 160 T/m

• Length 223mm

• Working pressure 15 bar hydraulic (16 bar pneumatic)

Strength points

• Reduced dimensions

• Vertical tool change of punches with antifall pins

• Automatic tool lifting and seating

• No extra space required for connection pipes

Promecam tang 7mm axis

Crowning wedge

Intermediate

Hydraulic supply with retractable fitting. (The different intermediates have to placed one next to the other and after final assembly will look like a single clamping)

Hydraulic front clamp

Insert for punch lifting and seating

Polyurethane insert to clamp segmented tools properly